About Company

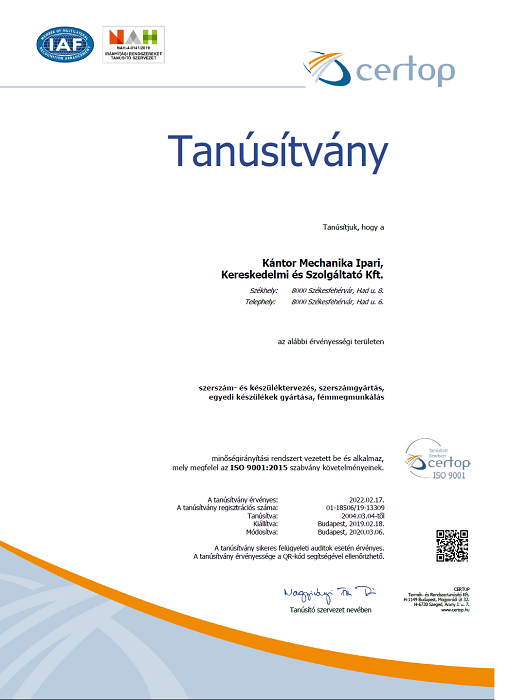

Kántor Mechanika was founded in 1993 as a Hungarian mechanical company. It is a certified as a free of public-debt company and highly qualified taxpayer.

Founder of the company: Sándor Kántor

Owners: Sándor Kántor and his son, Attila Kántor

Main activity:

Cooperation with multinational companies in the full range of mechanical, design, cutting, locksmith (metal joinery) and measuring industries. According to standard requirements, we have several decades of experience in the following areas:

- CAD design

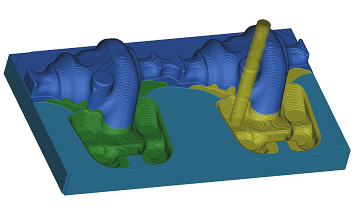

- CAM-programming

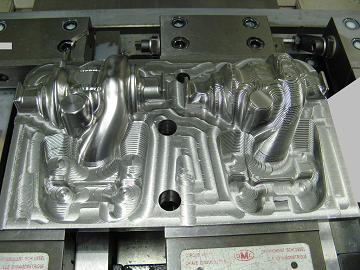

- CNC-manufacturing

- CMM-measurement

Our production procedures:

- CNC and conventional milling

- CNC and conventional turning

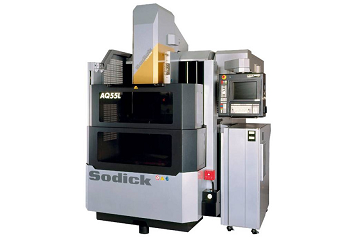

- CNC wire EDM

- CNC block EDM

- CNC coordinate measurement

- laser welding

- surface and cylindrical grinding

- heat treatment, browning, surface treatment

- measurement and material testing

- locksmith industry procedures

Specialized areas over the years:

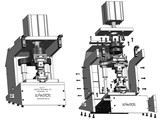

- design, manufacture and quality assurance of machine tools

- design, manufacture and quality assurance of fixture tools

- production of individual and small series parts

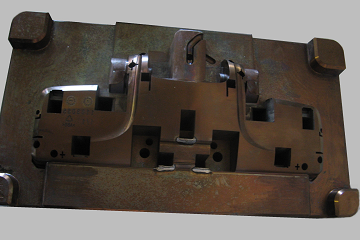

- design and manufacture of tools, moldings and gauges

- design and manufacture of carrier plates, material transport wagons, production lines

- design and manufacture of injection molds

- Direct Computer Control CMM measuring in our laboratory and make measurement reports

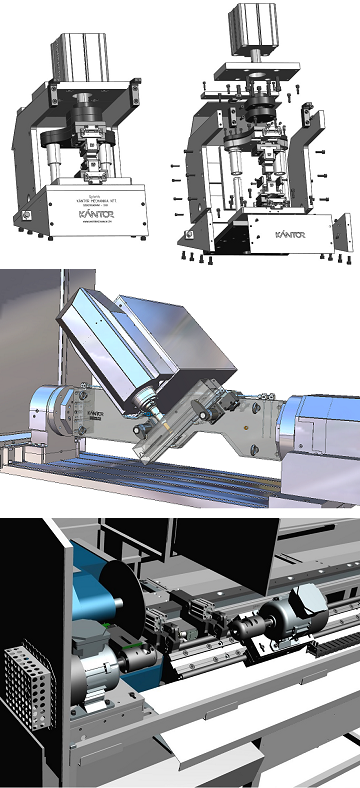

We are the official machine rebuilder for several CNC machine brand. We get orders from factories in such cases when the buyer wants to purchase machines on individual requirements.

Including the following:

- mounting the 4th axis for 3-axis machines

- design and construction of hydraulic rotary unions

- designing and manufacturing custom hydraulic, pneumatic and toggle clamped fixture tools, specially for machining automotive body parts

- machine rebuild, by re-designing and replacing the cover elements of the machines (machining area expanding)

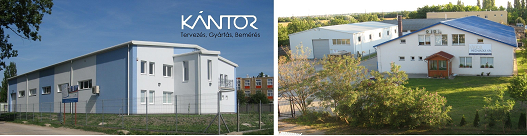

We do our activities in our own new modern factory halls on thousands of square meters, in the Infrastructure-Friendly Entrepreneurial Center of Székesfehérvár. There are several companies, hotels and petrol stations in the neighbourhood, and we also have the Fejér County Regional Tűr István Training Center. Our company is still under serious development. In addition to increasing our capacity, new technologies are being introduced. We would like to meet the new and emerging challenges of the future, to fully satisfy our customers' needs.

We have a number of world famous companies such as Alcoa (Arconic), Ford, Grundfos, Harman, Kongsberg, Magna-Cosma, Musashi, Philips, Sapa (Hydro), TP Vision, Videoton, Visteon (Hanon Systems)

We thank all our partners and employees who have contributed to our development and our successes. Based on the results so far, the managing director Sándor Kántor, received the 'Entrepreneur of the Year' award in 2009 in Székesfehérvár, and in 2012 'The award for Székesfehérvár's Economy'.

Related press releases:

Current Form of Business Ltd., Tax Number 11454025

It is a certified as a free of public-debt company and highly qualified taxpayer.

Query number: 11454025

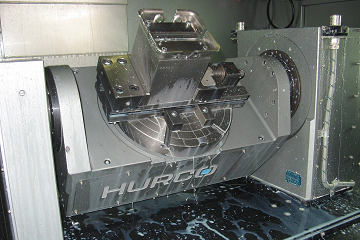

In early 2010, we launched our new high-performance HURCO CNC milling machine

In early 2010, we launched our new high-performance HURCO CNC milling machine